When your business encounters a hydraulic cylinder leaking issue, there are many reasons why you should immediately address the situation. Efficient hydraulic ram repair services for industrial appliances will promote safer working environments, reduce carbon footprints, and increase productivity. Above all else, though, it will protect your company’s finances by preventing downtime.

Here at FluidKraft, our hydraulic repair Sydney, experts can provide a range of hydraulic ram repair services to get your business firing on all cylinders once more. Here’s everything you need to know about why addressing the issues is so vital for preventing downtime in your daily operations.

Firstly, just how important is it to prevent downtime?

Unscheduled downtime is a business killer. Large organisations across Australia admit that every hour of downtime costs them over $100,000 while even smaller companies with just a few employees lose an average of $2,000 to this issue. Hydraulic cylinder leaking is just one of many causes of downtime, but it is arguably one of the most problematic – especially if businesses do not address the situation quickly.

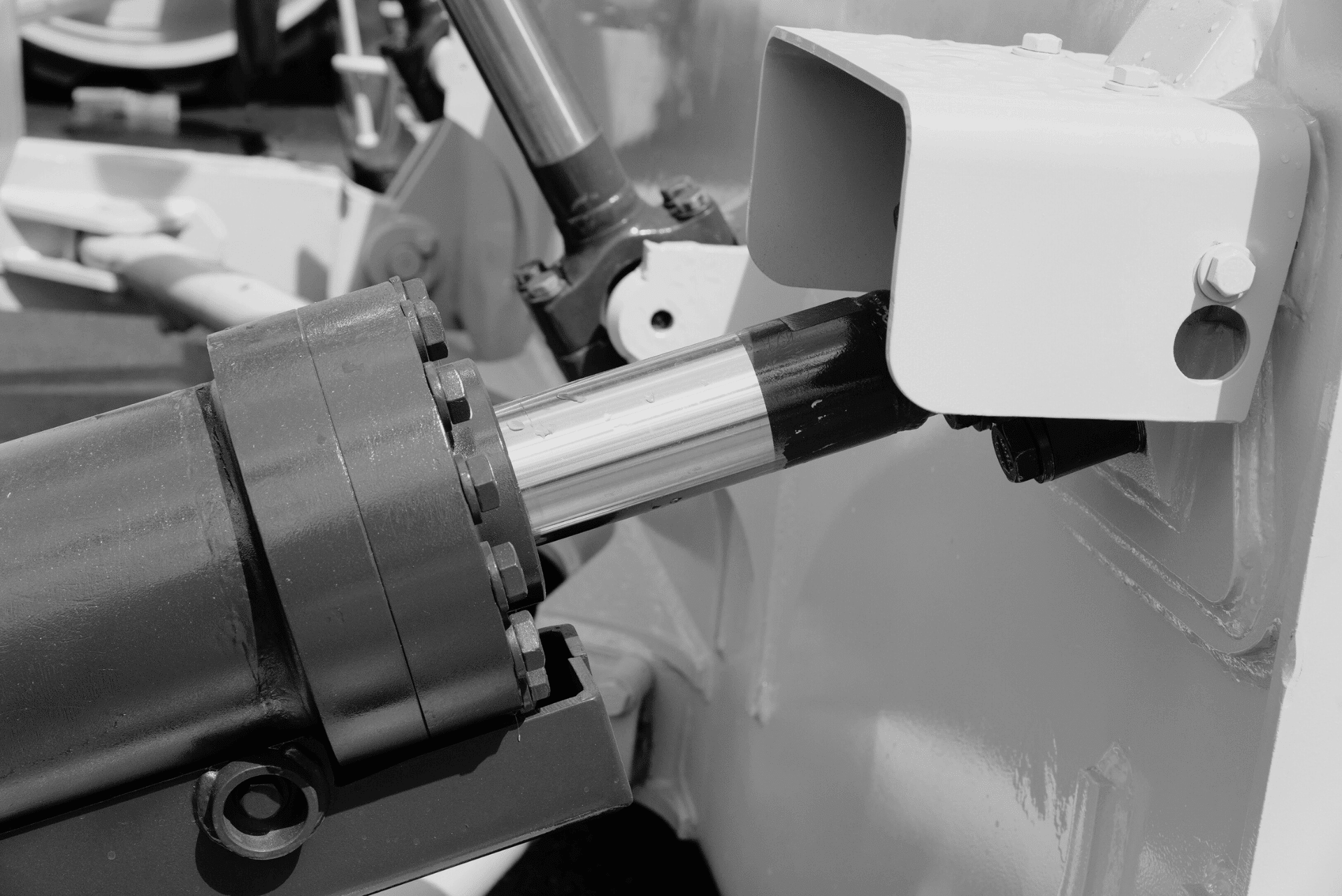

Hydraulic cylinders are a key component used within various types of construction equipment, agriculture tools, manufacturing products, and engineering equipment. Sadly, when the linear motion becomes impacted due to wear and tear or other forms of damage, machines will be unable to efficiently convert hydraulic energy to mechanical energy. In turn, this means that the heavy-duty functions cannot be completed. Worse still, if the hydraulic cylinder leak is allowed to worsen to a point where it causes downtime, the repercussions include but are not limited to;

- Lost productivity involving the affected equipment as well as any subsequent processes in the manufacturing or engineering assignment.

- Lost sales as a result of poor productivity and ability to satisfy the demand.

- Reduced employee morale as they become frustrated by being unable to complete their tasks due to broken tools or equipment.

- Damaged brand reputations with consumers and retailers that expect your products.

- Increased repair costs because the damage has been allowed to grow and potentially spread to other parts of the machinery.

Whatever the application of your custom hydraulic cylinders might be, you should never ignore leaking or other signs of damage. Preventing downtime through quick action will benefit the employees, clients, and business.

How to address hydraulic cylinder leaking

The best way to prevent downtime linked to hydraulic cylinder leaking is to keep hydraulic cylinders in good health. You can do this by regularly inspecting the hydraulic seals, confirming that the rods are straight, and completing basic maintenance by using a Hydraulic Stop Leak solution. Whether it’s mining or manufacturing, those steps will help all industrial applications. Nevertheless, it is impossible to prevent wear and tear, which is why even the most careful businesses may experience a hydraulic cylinder leak from time to time.

When this happens, the goal is to get your machinery or equipment restored to full working order without causing unnecessary downtime. As a business owner, the DIY route may sound appealing. In reality, though, using a professional hydraulic repair Sydney service like FluidKraft is the best choice by far. Here are just some of the reasons why calling an expert will serve you well;

- FluidKraft’s experts can quickly identify the source of the leak, ensuring that the right type of restorative work is subsequently completed. If you were to take on the challenge, there is every chance that you would fall into the trap of an inaccurate diagnosis that results in unnecessary ‘repairs’.

- We are fully qualified to offer hydraulic ram repair across all applications and industries while also working with custom hydraulic cylinders. Likewise, we can handle everything from simple tasks like replacing seals and barrel hone to manufacturing new rods via our off-site plant.

- Our experts work far quicker than your workers. In situations where minor leaking hasn’t caused downtime, our local hydraulic repair Sydney experts can complete the restorations during out-of-work hours. So, even the repair job itself needn’t have any detrimental impact on productivity or performance.

- As experienced hydraulic ram repair specialists, we will complete all restorative work using the right tools, techniques, and parts. Moreover, our post-repair tests will confirm that your applications and machinery are as good as new. So, you can rest assured that there will not be a repeat.

- In addition to providing peace of mind regarding the quality of the repair work, FluidKraft’s commitment to communication means that our experts will also advise you on future preventative steps and maintenance work that will keep your heavy-duty machinery operating at optimal health for the long haul.

In short, attempting to complete the hydraulic ram repair processes yourself will likely lead to delays while simultaneously leaving you with a far less effective outcome. This means that there is every chance that a repeat hydraulic cylinder leak will surface at some stage. For the sake of productivity, profitability, and your sanity, contact our hydraulic repair Sydney experts today. We will find the most efficient and cost-effective solution in no time.