Almost every industry we engage with uses hydraulic cylinders in some way. From the machines that are used to build our homes, to the workout equipment we fill them with, hydraulics are everywhere. But what are the different parts to a hydraulic cylinder, and what roles do they serve?

To help you identify the differences in these fairly similar hydraulic systems, we’ve prepared this handy guide. This article describes the basic differences between single-acting and double-acting hydraulic cylinders.

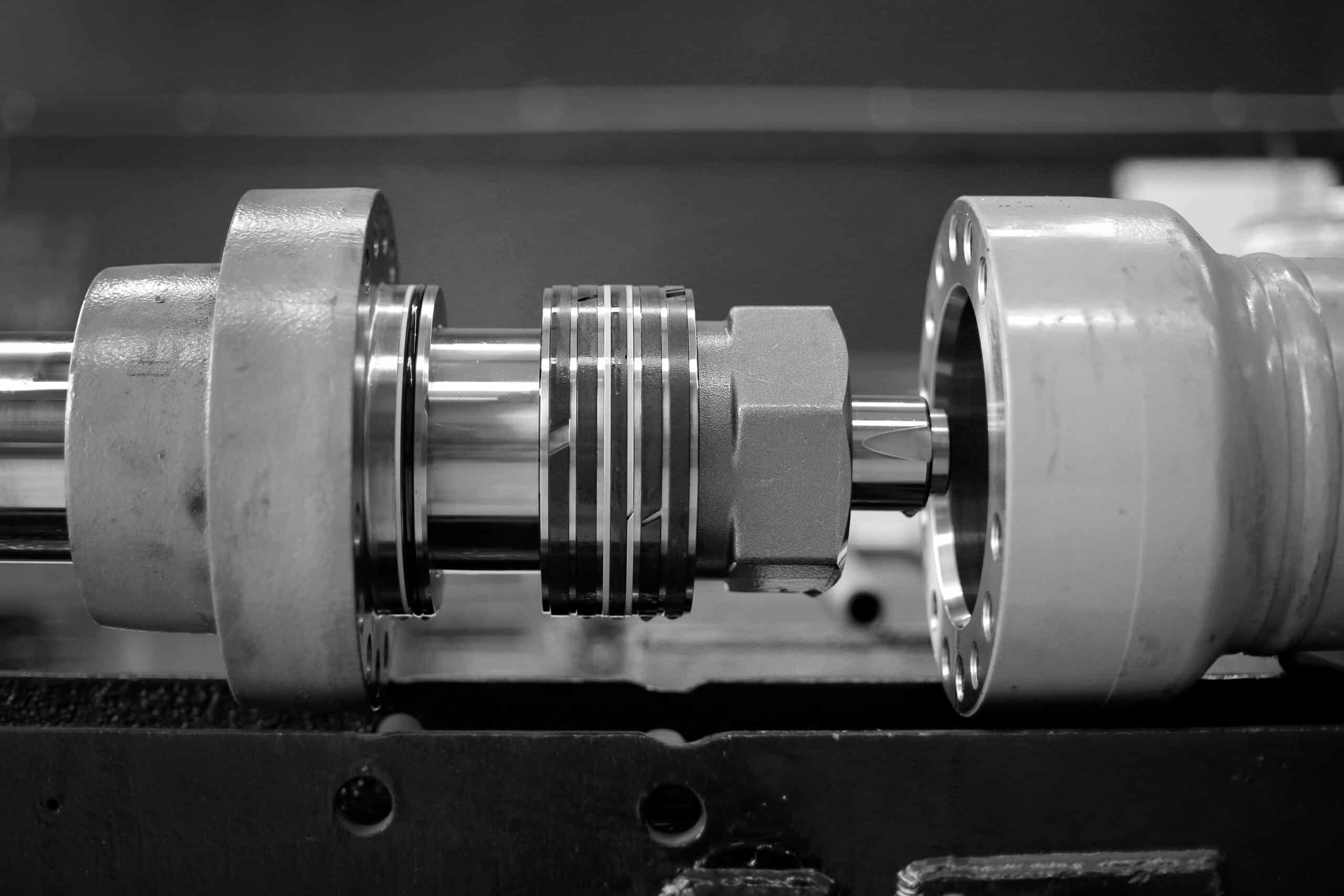

A Hydraulic cylinder is made up of a clevis, end cap, port, piston and piston rod, a seal gland and finally a seal. This hydraulic cylinder works by pressurising a fluid sealed within the cylinder, to force the piston to extend and retract with great speed and force.

It’s important to know what each part of a hydraulic cylinder does and how it interacts with the rest of the system. If you ever need to disassemble, reassemble or perform hydraulic cylinder repairs, understanding the components inside is crucial.

For this reason, we have put together this complete guide to hydraulic cylinder parts. Read on to learn all about hydraulic cylinder components and how they’re assembled.

What Are the Different Parts of a Hydraulic Cylinder?

A hydraulic cylinder has eight basic components; the clevis, gland, port(s), barrel, rod, piston, the end cap, and the seal. When combined, these parts allow the hydraulic cylinder to pressurise fluid that mobilises a piston to generate power for a machine.

Hydraulic cylinders and rams power most of our machinery, but the core design is more than two centuries old. The construction and design of hydraulic cylinders have not changed since they were introduced back in the 1790s.

Being a type of mechanical actuator, or ‘motor’, these parts are engineered and built to work together to execute a specific task — to extend, to retract or both. The power itself is provided by a hydraulic pump.

The basic parts that make up a hydraulic cylinder include:

- Clevis (Cylinder Cap) – The clevis is the part of the hydraulic cylinder that is mounted. The mounting option (such as the Clevis) is attached to the Cylinder Cap, which keeps the pressure in the barrel.

- End Cap (Cylinder Head) – Works with the Cylinder Cap to keep the pressure inside.

- Port – Where the hydraulic fluid flows to or from.

- Piston – The part which exerts the pressure.

- Piston Rod – The part which transfers the force onto the piston itself.

- Cylinder Barrel – Where the pressure is contained.

- Gland (Seal Gland) – Stops the pressurised fluid from leaking past the piston rod and cylinder head’s point of connection.

- Seal – Prevents the fluid from exiting or escaping when the piston is in motion.

There are a range of mounting options for hydraulic cylinders and rams, including lugs, flanges, clevises and lug mounts.

The Clevis

The clevis is a type of mounting system for hydraulic cylinders. This piece in particular is a pivot mount — one that allows the hydraulic cylinder to pivot in a single range of motion along an axis.

The cylinder cap is where mounting options like the clevis are attached to. This is one of the most commonly used mounting systems, and is mostly used in applications that require the cylinder to pivot through an arc when retracting and extending. Clevis mounts see the majority of their usage in mobile industrial or construction plant hydraulics such as excavator booms. They are also mostly used in hydraulic cylinders that are short stroke, and small to medium-bore.

Mounting brackets are first fitted into the ends of the hydraulic cylinder, and then inserted into the clevis mount, where a steel pin holds it in place with cotter pins, or snap rings. This method forms a pivoting joint assembly for the hydraulic cylinder. The clevis mount provides a centerline mounting advantage to the hydraulic cylinder, although it has some vulnerability to side-load issues due to its singular range of motion. To lessen these effects, spherical bearings will sometimes be used in clevis mounts to allow a marginal degree of misalignment. This in turn improves the hydraulic cylinder’s lifespan and avoids premature hydraulic cylinder failure.

Other types of hydraulic cylinder mounting options include:

- Flange Mount – A method of mounting the hydraulic cylinder off its head. It is a flat plate where the cylinder rod passes through and is secured to. There are no joints or bearings, and the mount is fixed centre-line of the hydraulic cylinder. This provides an incredible amount of strength and stability.

- Trunnion Mount – This is basically a cylindrical extension which forms a mounting point, similar to a tree stump. These were originally used for old cannons you have seen in wooden battleships, where they were used as mounting points, allowing it to pivot up or down.

- Lug Mount – A fixed-style mounting option which has a rectangular tabs machine or welded onto the hydraulic cylinder’s head and cap. This kind of mounting option offers a good amount of strength and stability, but is susceptible to the same intolerance to misalignment as other fixed-type mounting options.

The End Cap

The end cap covers the pressure chamber from one end of the hydraulic cylinder. It is also referred to as the cylinder head, or the “blind end” due to its placement inside the cylinder barrel, removing any exposure from sunlight.

End caps are connected to the hydraulic cylinder’s body through bolts, rods, or threading. They also have the option of having either a seal gland, or an integrated rod sealing arrangement.

The Port

The port (or ports in double acting hydraulic cylinders) is where the fluid enters and exits the system. On double acting hydraulic cylinders, each port is located at either end of the hydraulic cylinder, with the piston in between both ports.

It is essential for ports to be highly secure as any weakness in its design may result in a dangerous leak of pressurised hydraulic fluid. When repairing hydraulic cylinder leaks, this is one key area to inspect.

The Piston

Located within the hydraulic cylinder, the piston separates the pressure zones inside the cylinder’s barrel. The back and forth action that the entire piston system creates is what generates power.

The piston rod is attached to the piston using threads, nuts, and bolts to transfer the linear motion. Pistons come in two different resting states; one that is ‘sprung in’ (piston rests in a retracted position), and another that is ‘sprung out’ (piston rests in an extended position). Knowing the resting state of the pistons in your hydraulic system is important to know if they are stopped mid-action by something like a blackout.

The different resting phases also mean that pressure is applied in different parts of the hydraulic cylinder. For instance, when pressure is applied onto the end cap, the cylinder rod will extend.

The Rod

Also known as the piston rod, this is one of the most fundamental and critical parts of a hydraulic cylinder. The rod is the piece of the piston that extends and retracts, generating the movement the hydraulic cylinder requires to function.

The piston rod is attached to both the piston and the cylinder head. It connects the hydraulic cylinder into a machine used to do work in the form of either a mounting attachment or a machine thread. This is in charge of transmitting the force created by pressure to the machine component. The polishing and finishing of piston rods are crucial to prevent leakage, so this should always be performed by a reliable hydraulic repair workshop.

The Barrel

The hydraulic cylinder tube is what’s keeping the pressure inside the cylinder, and houses the piston. Hydraulic cylinder barrels have to be made from highly durable materials to endure the stress and pressure they are put under.

These parts are made from varying kinds of steel, each having its own different degrees of strength. The metal required will depend on the type of hydraulic cylinder and the application.

The Gland

Also known as the hydraulic cylinder gland, or ‘seal gland’, the gland is equipped with a number of seals which will prevent pressurised fluid from leaking beyond the piston rod or the cylinder head. These are essential as fluid leaks can cause misalignment and damage within the cylinder.

As mentioned earlier, the end cap can either have a seal gland, or an integrated rod sealing arrangement. The benefit of a seal gland is that it allows for an easy removal and replacement of all the seals in the hydraulic cylinder.

The seals located inside the seal gland are the:

- primary seal

- secondary seal

- wear bands

- wiper

- crapper

- static seal

The Seal

Seals are found throughout the hydraulic cylinder, and are made from varying materials depending on the application to prevent leakage within the system. They are designed to be able to survive repetitions of the piston rod moving in and out the cylinder barrel.

Designers and engineers choose seals based on the hydraulic cylinder’s application. For instance, seals that are resistant to melting will be used for hydraulic cylinders that operate in extremely high temperatures. On the other hand, those that are used in very low temperatures will require seals that are made from polyurethane, since the material does not crack in very low temperatures.

For hydraulic cylinders that have to withstand applications that undergo a lot of friction (i.e. factory environments), Zurcon and PTFE seals are usually used. There are also specialist seals that are designed with back up rings (those that work under extreme pressure) as well as seals that are designed to have a very tight closure (for hydraulic fluids that are capable of leaking out of standard seals).

In case of a leaking hydraulic cylinder, damaged seals are another key component that could be causing the problem.

How are Hydraulic Cylinders Assembled?

Assembling a hydraulic cylinder is a relatively straightforward process, with each part attaching to the other in a specific manner. The assembly can only begin after each part is inspected for its quality and cleanliness.

The basic steps for hydraulic cylinder assembly are:

- First, the seals (for the piston, cylinder head, etc.) are placed in their respective positions along with the bearing and snap ring.

- The cylinder head and the piston are then attached to the cylinder rod.

- The seals around the cylinder head and piston are oiled.

- Once the piston rod is assembled, it is then ready for tube installation

- The tube is horizontally fitted to an installation bench, in which a bearing is installed and the tube is meticulously oiled from the inside.

- The piston rod is then inserted into the tube, with the piston end first.

- Once these are finished, the grease nipples and bearings are then installed.

During each and every step, the assemblers’ top priority is the cleanliness of the parts. Avoiding contamination is a major priority in hydraulic cylinder maintenance, so the surfaces are kept clean, and wiped when necessary. Regardless of the type of cylinder, the assembly process more or less stays the same.

As you would expect, different hydraulic cylinders will also have varying assembly times — simpler single acting hydraulic cylinders will take less time to assemble than more complex double acting hydraulic cylinders.