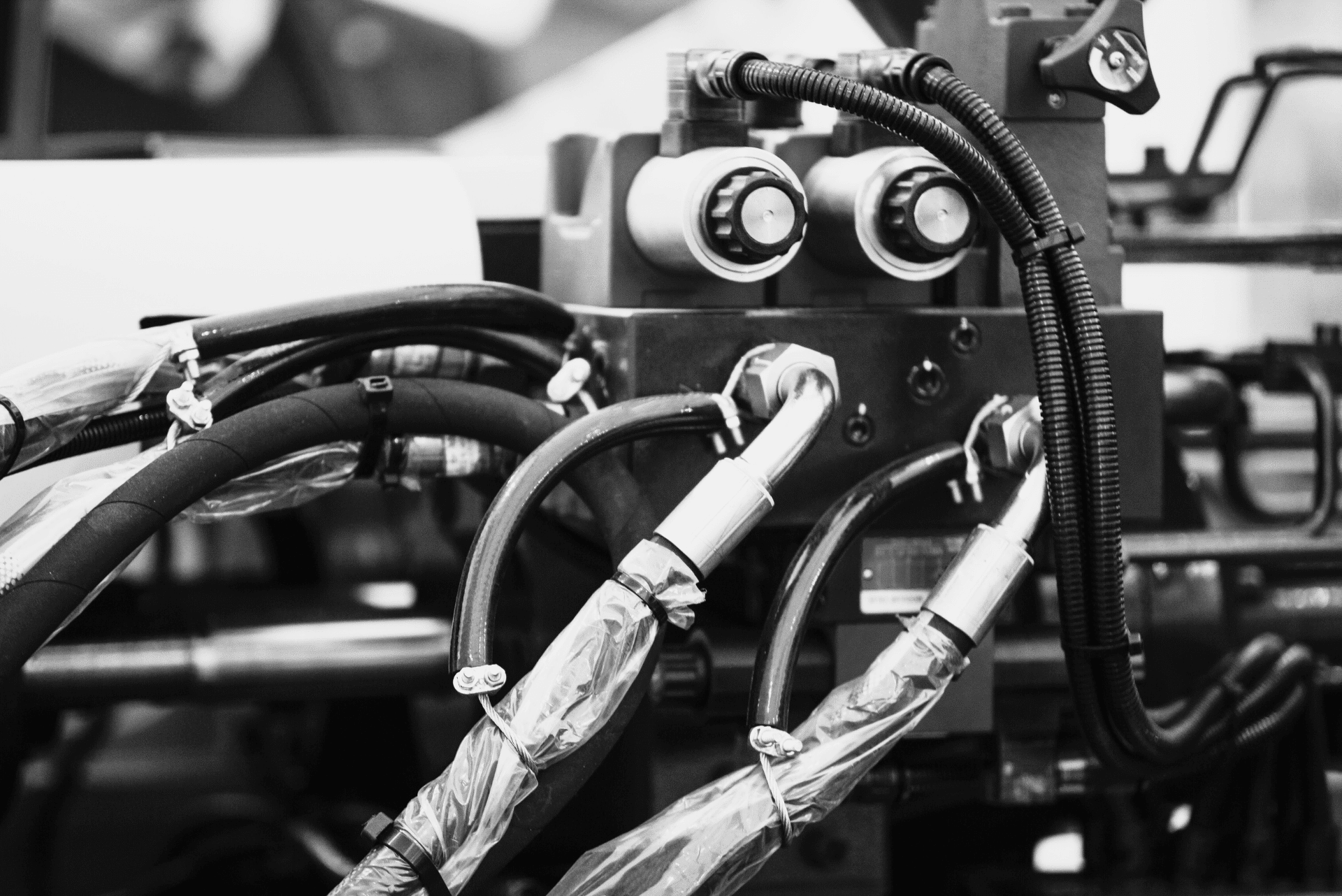

Effective hydraulic systems rely on closed operational loops that enable the transfer of pressurised fluids from one point to another. Hydraulic fittings, which connect hydraulic hoses to other components, are essential for this process and are used for a wide range of applications such as manufacturing, construction, and agriculture.

Threads ensure connections between different hydraulic components, while seals secure those connections to create the closed loops that operational hydraulics depend on. Unlocking the power behind these crucial hydraulic fittings ensures industry-specific functionality, and the longevity of hydraulics systems overall.

But, what are seals and threads, and how can you ensure that they always perform at their full potential within your system?

What are Hydraulic Threads?

Hydraulic threads play an essential role in any hydraulics system by enabling connections and seals between different hydraulic components. Each different type of thread used within a system will serve a different purpose, such as connecting pipes or connecting hoses.

Types of Hydraulic Threads

The three primary types of threads used within hydraulics systems include –

- National Pipe Tapered (NPT): NPTs are tapered threads that are most commonly used for joining hydraulic pipes and fittings. The angle of the taper on an NPT thread is 1⁄16 in./ft, which allows the formation of a seal when NPTs are tightened against another tapered thread.

- British Standard Pipe Taper (BSPT): BSPTs are commonly used within hydraulics systems, and typically join hoses together, or connect hoses or ports. BSPTs have a 60° angle with a rounded crest and root.

- Joint Industry Council Thread (JIC): JIC threads are metal-to-metal sealing threads that have a 37° flare according to original design specifications from the Society of Automotive Engineers (SAE).

Hydraulic Thread Maintenance

Damaged or poorly maintained hydraulic threads run the risk of serious hydraulic leaks. These can impact the whole system, meaning that proper maintenance of your threads is essential. To deliver this, it’s crucial that you understand which threads your hydraulic system uses, as well as any limitations of those threads. With this information, it’s possible to unlock the true and lasting power of these hydraulic hose connector fittings through regular inspections, cleaning, and lubrication, as well as immediate replacement if any damage occurs.

What are Hydraulic Seals?

Hydraulic seals are most often created using different types of o-rings which seal the openings between different components in a hydraulic cylinder. Seals are crucial for preventing leakage and contamination, either of which could significantly damage a hydraulic system. Seals can be moulded or carefully designed using simulation software, and tend to be made out of delicate materials such as rubber and Polyurethane. Secure seals are essential for the functioning of your hydraulics systems.

Types of Hydraulic Seals

- Piston seals: Piston seals are single-acting seals that guarantee liquid doesn’t pass round the piston by containing fluid on the correct side, while allowing the movement of the piston rod.

- Wear rings: Wear rings are used within rod and piston installations to keep the piston centralised. This ensures even wear and stress allotment on the seals.

- V-rings: V-rings are self-retaining seals that are used on moving parts to apply low-contact pressure against the counter surface and maintain seal function.

- Rod seals: Rod seals avert the leakage of fluid from inside the hydraulic system to the outside to guard hydraulic configuration against outside contaminants like dust.

Best Practices for Hydraulic Seal Installation

If hydraulic seals aren’t properly installed, your hydraulic system may malfunction. To ensure proper installation, it’s important to –

- Inspect your seals: Inspect all seals properly before installation and never install a seal that shows signs of damage.

- Protect your seals: Fragile seals should be protected throughout the installation using the correct tools, sleeves, or mounting tubes.

- Lubricate your seals: All seals should be lubricated with a liquid that is compatible with the fluid used with the hydraulic system, as this enhances durability and prevents abrasion.

- Check the orientation of your seals: Before installation, check that seals are correctly orientated to the fluid direction of your hydraulic system. Incorrect orientation can lead to early failure of the seal.

How Do You Unlock the Power Of Seals and Threads?

Seals and threads are essential to the smooth running of any hydraulic system across countless industries and have the power to significantly enhance hydraulic function. Unlocking this power depends on your ability to –

- Understand the best threads and seals for use across your hydraulic system

- Ensure proper installation of all threads and seals

- Oversee regular maintenance and servicing

If you notice damage to your threads and seals, it’s fundamental that you act fast either in-house or by searching for hydraulic hose repair near me and entrusting this crucial task to professionals like our team here at Fluidkraft. Then, you can ensure that you’re always unlocking the full potential of the seals and threads within your system.