Hydraulic hoses are ubiquitous in engineering, construction and other industries. Hydraulic hoses are used in various types of machinery, equipment and vehicles. Unfortunately, they can sometimes sustain damage and break, even though they are typically pretty durable. They can spring a leak, which potentially leads to further problems such as increased costs or a drop in productivity.

The best thing to do when you need hydraulic hose repair is to leave it to a professional. However, there are also times when you can carry out a temporary repair when you need a quick fix. It might seem like a tricky task, but it could be simpler than you think. Of course, some things can go wrong, and you want to perform a repair that holds up. If you want to make sure you get a smooth fix, take a look at the following tips to get it right.

Find the Right Hose

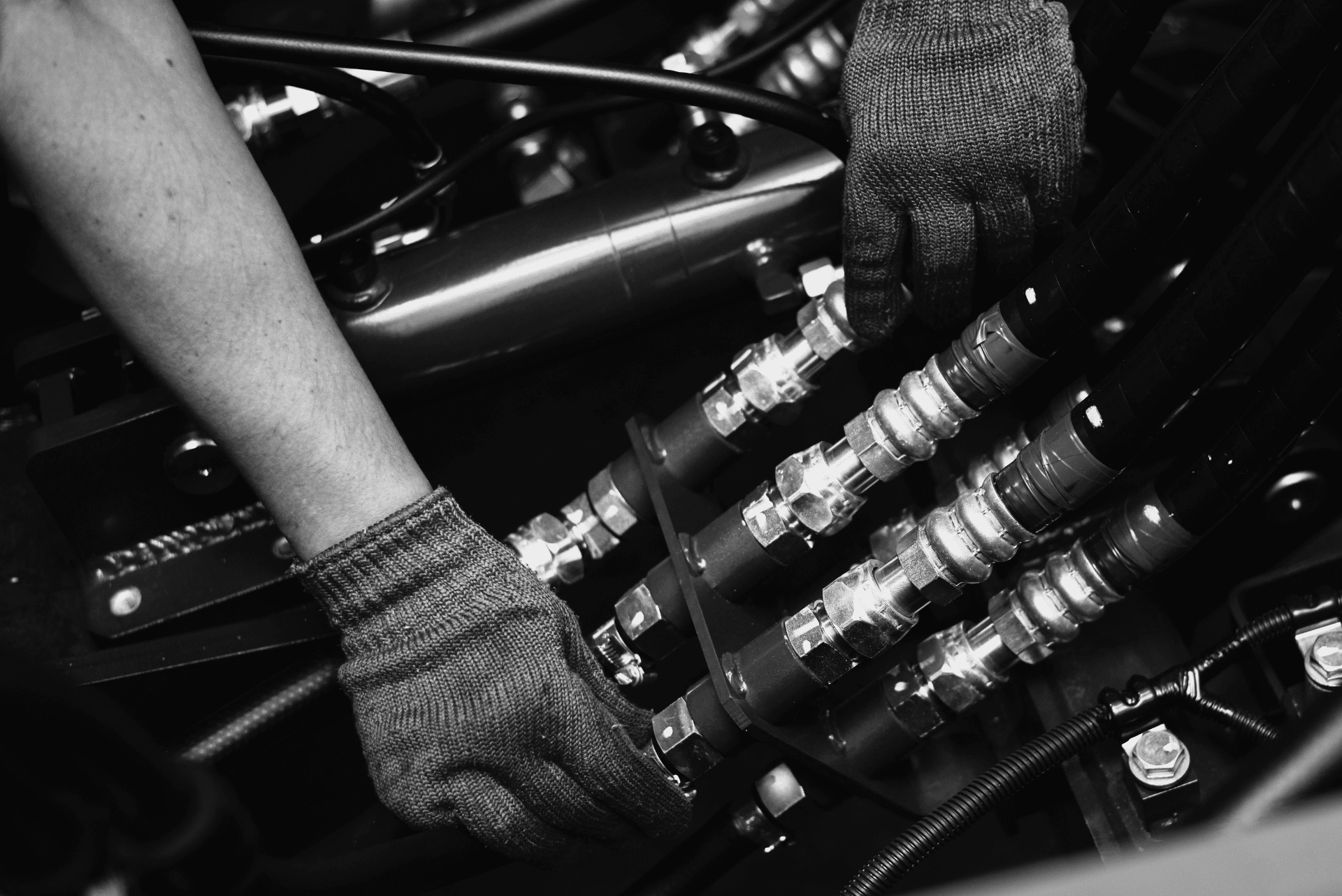

Getting the right hose is an important step when you need to perform a repair. There are often multiple hoses that perform different functions and have different minimal pressure tolerance. So finding not just the hose that requires repair but also the specification of the hose is essential. It’s crucial to get the right replacement hose or it could be very dangerous. Always speak to a professional if you’re not sure. Additionally, when dealing with hydraulic systems, consider the importance of hydraulic hose connectors fittings. Ensuring compatibility with the hydraulic hose is vital for a secure and efficient repair or replacement. Take the time to understand the specific requirements of your hydraulic system and select the appropriate “hydraulic hose connectors fittings” for a reliable and safe operation.

Cut Out the Damage Piece of Hose

Removing the part of the hose that has been damaged is the next step. After you have cut it away, clean around where you have cut to remove any contaminants. You need to thoroughly clean the area because even a small particle could cause internal damage.

Use the Right Adapter

When you need to install a new piece of hose, you might need a hydraulic adapter. Ideally, you would have the correct hydraulic coupling. But because that’s not always practical or possible, carrying a kit with several different adapters can be useful instead. Install the adapters into the relevant ports to create a complete connection. You will need to tighten the adapters and couplings properly for a safe and effective repair. Don’t make it too tight or too loose if you want to get it right. Again, it’s a good idea to get professional help if you’re not sure what you’re doing.

Get the Right Hose Length

You will need to check that you have the correct length of hose for its purpose. If it has to stretch too much or you can’t install it in the right way, it can put too much pressure on the hose and other components. If it’s a little too long, it will matter less than if it’s too short. However, getting the ideal length is the best thing to do.

Checking the length is the first part, but you will then have to check that you route it in the right way. Routing it correctly should mean that the hydraulic oil can flow more effectively and the system can function as it should. In some cases, an angled adapter or coupling could be needed to position the hose correctly. The end of the hose can then be attached to the adapter or port, once the hose is in the best position.

Get a Firm Seal

A proper seal is vital for hydraulic hose repairs. When you attach the other end of the hose to the opposite port, double-check that you have a good seal. The smallest gap could lead to a leak and allow problems in the system to develop. It should be firmly attached without being too tight, as this could put too much stress on it. You can tighten it with a wrench but make sure you don’t over-tighten it. Avoid twisting the hose so that there is no undue pressure put on it.

Test for Leaks

After replacing the length of the hydraulic hose, you should check for leaks to ensure it’s all functioning correctly. Circulate the oil or fluid through the system using a low pressure to test it. This will give you a chance to look out for leaks and connections that need fixing, while also removing any air that might be inside. Do this for a few minutes and check for leaks again. Use some paper or cardboard to identify any leaks. Using a fluid with dye makes it easier to find any leaks.

If you’re not sure how to approach a hydraulic hose repair, look for hydraulic hose repair near me or contact the expert team at FluidKraft at (02) 4660 0126 or inquire here, today.