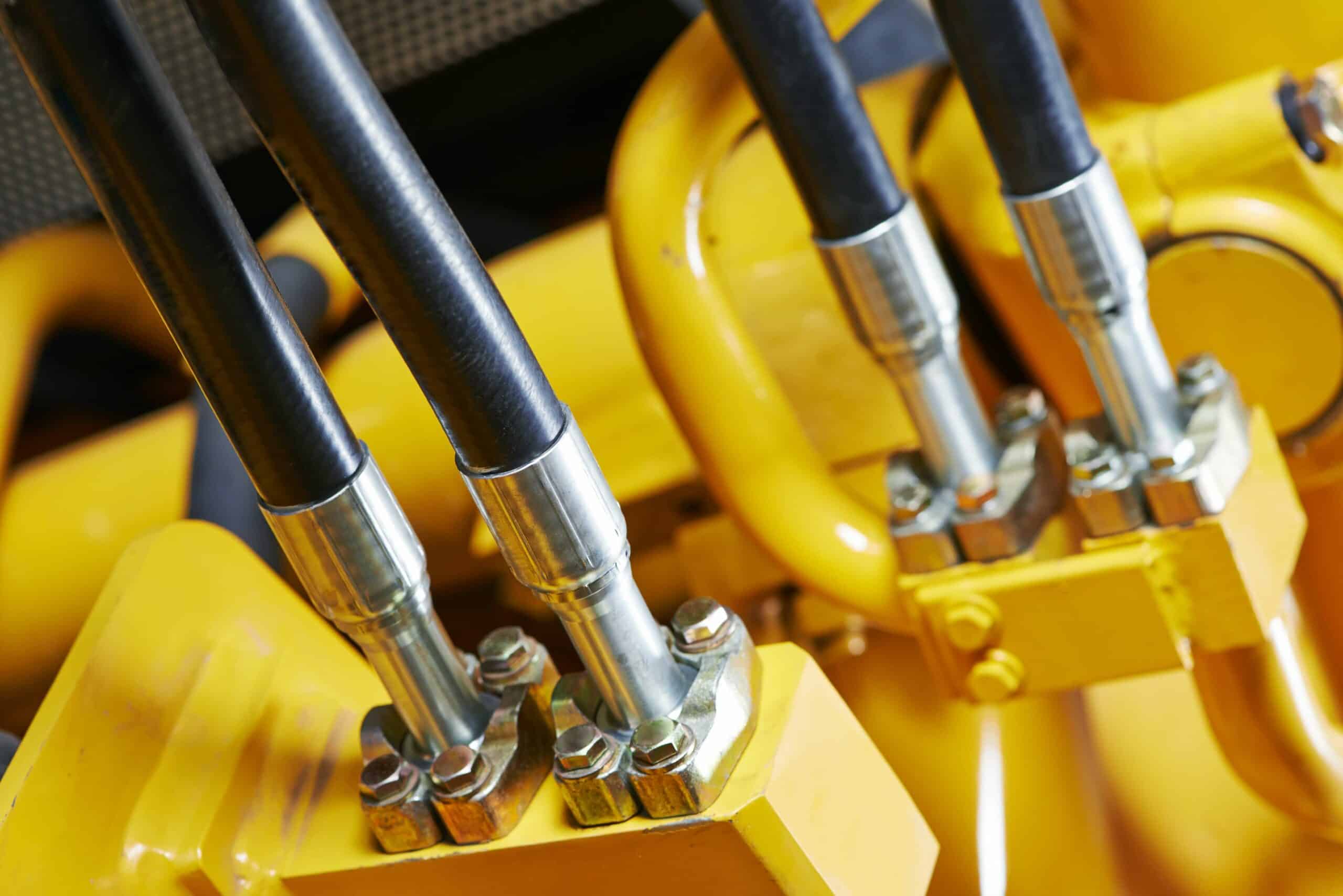

HYDRAULIC HOSE REPAIRS SYDNEY.

SERVING NSW AND SURROUNDS

Hydraulic hose repairs are an integral part of the services we offer and FluidKraft is the gold standard when it comes to mobile hose repairs.

Our goal is to help you minimize downtime by providing you an efficient and cost effective mobile hose repair solution that will help you reduce cost and maximize uptime.

Call 02 4660 0126 any time to be diverted to our on call Mobile Service Technician.

Request a service call.

Fill out the form below and we will contact you shortly.

"*" indicates required fields

The FluidKraft advantage.

24/7 Hose Repair Service.

We regularly hear “I can’t stop my gear at the moment to fix this rubbed hydraulic hose, we will just fix it when it breaks.”

While we appreciate that no one wants unscheduled downtime, but having a damaged hydraulic hose is not only a safety hazard, It’s much worse to have a hydraulic hose burst when your equipment is covered in mud on a wet winter worksite then to repair damage hoses when the machine is clean and on your own terms to cause minimal disruption.

Our goal is to help you minimise downtime by providing you an efficient and cost effect mobile hose repair solution that will help you reduce cost and maximise uptime.

Rock solid trust in our services.

Tips to minimise the chance of damaged hydraulic hosing.

There are a few simple steps that you can take in order to minimize the risk of having a hydraulic system failure due to damaged hoses. First, we need to identify how a hydraulic hose gets damaged, hoses age regardless if they used in ideal conditions or in the field.

Hose failures don’t necessarily mean that your product is of poor quality, far from it, as all of them are subjected to almost constant wear and tear on the site. About 80% of hydraulic hose failures are caused by other equipment or external damage (i.e. abrasion). This is due to hydraulic assemblies rubbing on each other or its surrounding surfaces which create friction, and ultimately heat, that can soften the rubber after some time.

You need to identify the most obvious signs of a failing hydraulic hose. Some of these signs are cracking, blisters, and bubbles in the hose itself, we recommend that you conduct a running regular visual inspection and add to you regular daily. It is important that your operators to NEVER run hands or body parts across hydraulic hoses to check for leaks as a pin pricked hose leaking hydraulic oil could lead to serious injuries.

When to replace a hydraulic hose.

There are a few simple steps that you can take in order to minimize the risk of having a hydraulic system failure due to damaged hoses. First, we need to identify how a hydraulic hose gets damaged, hoses age regardless if they used in ideal conditions or in the field.

Hose failures don’t necessarily mean that your product is of poor quality, far from it, as all of them are subjected to almost constant wear and tear on the site. About 80% of hydraulic hose failures are caused by other equipment or external damage (i.e. abrasion). This is due to hydraulic assemblies rubbing on each other or its surrounding surfaces which create friction, and ultimately heat, that can soften the rubber after some time.

This is all part of the normal life of a hydraulic hose and should be thought of as a consumable product.

You need to identify the most obvious signs of a failing hydraulic hose. Some of these signs are cracking, blisters, and bubbles in the hose itself, we recommend that you conduct a running regular visual inspection and add to you regular daily. It is important that your operators to NEVER run hands or body parts across hydraulic hoses to check for leaks as a pin pricked hose leaking hydraulic oil could lead to serious injuries.

HAVE A HYDRAULIC BREAKDOWN THAT NEEDS ATTENDING?

"*" indicates required fields