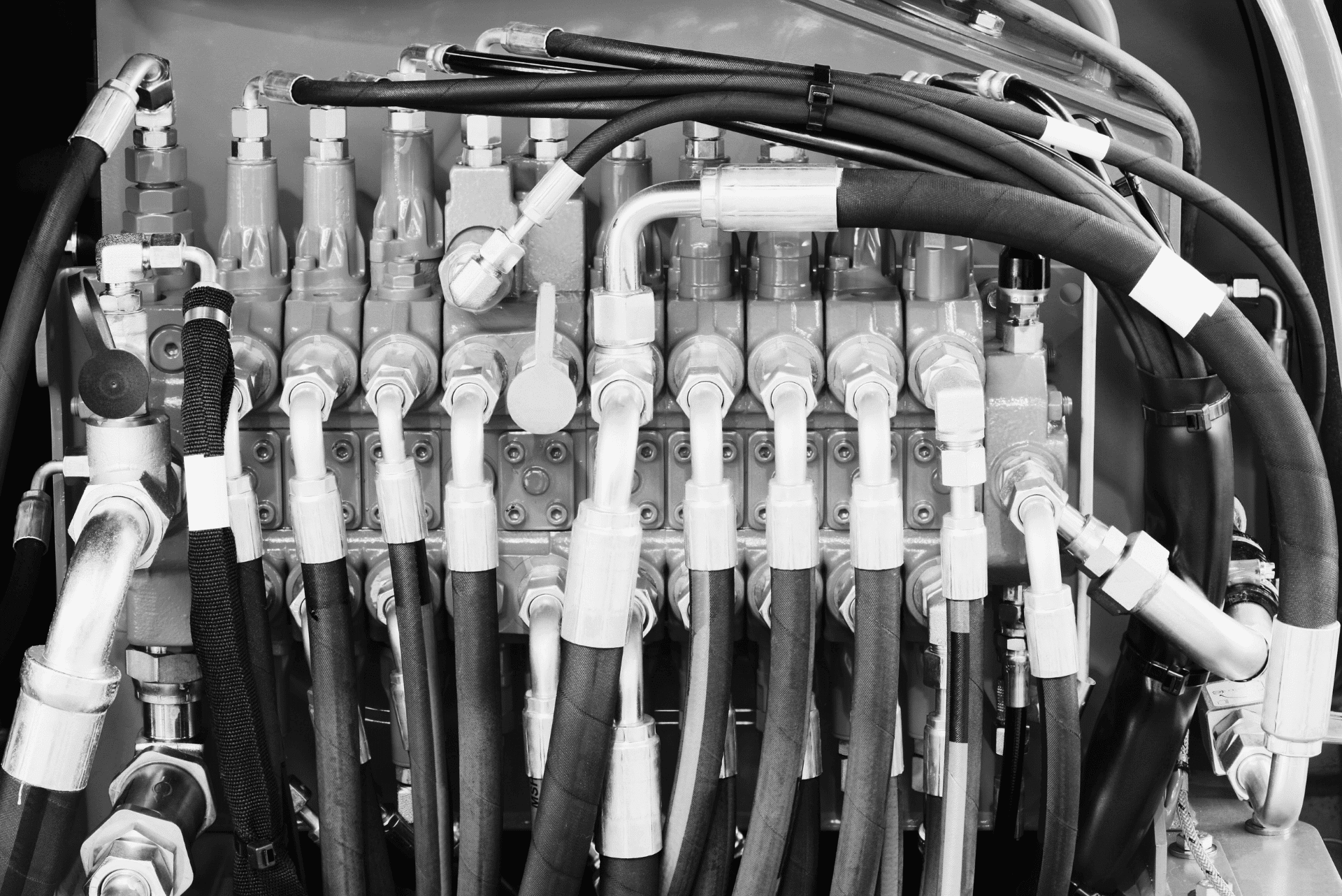

Hydraulic systems rely on the smooth, high-pressure transfer of fluid across various components including cylinders, pipes, and tubes. Hydraulic fittings connect hydraulic hoses to those components to avoid issues like contamination or leaks within a hydraulic system.

The use of hydraulic fittings is invaluable for maintaining the functionality and durability of hydraulic systems across industries including transport, manufacturing, and beyond. When used for the right applications, cutting-edge hydraulic fittings can even revolutionise how your systems operate overall.

In this article, we’ll consider why exactly hydraulic fittings hold such power, and how to choose the ideal hydraulic hose connector fittings for your unique application.

What Are Hydraulic Fittings?

Put simply, hydraulic fittings are fittings that connect hydraulic hoses to other components and machines within your system. All types of hydraulic pipes and fittings serve different purposes, whether that’s to help the flow of fluid, redirect fluid, or prevent leaks.

The most common materials used in hydraulic fittings include plastic, stainless steel or brass, depending on things like the amount of wear that fitting will receive, or the temperatures it’ll need to withstand. For instance, steel hydraulic fittings can withstand regular temperatures of up to 260°, while plastic hydraulic fittings struggle with even short exposure to extreme temperatures.

Different Types of Hydraulic Fittings

Generally speaking, hydraulic fittings slot into two primary categories, which are –

- Crimped Fittings: Crimped hydraulic fittings are a type of permanent fitting that requires the use of a crimping machine. Crimped fittings tend to be the most secure, but are more difficult to install.

- Field-Attachable Fittings: Field-attachable fittings are also commonly referred to as reusable fittings, and consist of a nipple and socket that can be installed anywhere, without the need for specific machinery.

Within these categories, the hydraulic fittings that stand to revolutionise your system the most include –

- O-Ring Face Seal (ORFS): An ORFS is a seal fitting that consists of an o-ring that can be connected with the flat face of the female connector. An ORFS will create a secure connection that’s ideal for preventing leaks during even heavy use. There are a range of different ORFS options available, including straight, elbow, and tee or cross ORFS fittings.

- Mated Angle Fittings: Mated angle fittings consist of a straight thread, and a tapered plane, or ‘flare’, going around the whole fitting. Rather than the threads themselves forming a seal, these flares are pushed together to create a seal.

- Tapered Threads: Tapered threads have male threads on the outside and female threads on the inside. Tapered threads deform when these fittings are threaded together, which applies pressure to create a seal.

- BSP (British Standard Pipe) Fittings: BSP fittings conform to BSP standards for screw threads, and are predominantly used in the plumbing industry to seal and connect hydraulic pipes and fittings using interlocking male and female threads.

Applications for Hydraulic Fittings

Hydraulic fittings are a crucial element of any hydraulic system, and each type offers a wide range of applications, the most common of which include –

- Factory applications including assembly lines and robotics

- Construction

- Mining

- Agriculture

- Transport

- Plumbing

- And beyond

To choose the right fitting to revolutionise your hydraulic application, consider key factors such as –

- Size

- Material

- Temperature range

- Pressure requirement

How Hydraulic Fittings Revolutionise Your System

The right cutting-edge hydraulic fittings can revolutionise a hydraulic system in a variety of ways. The most notable improvements you’ll see from putting the correct fittings in place include –

- Increased functionality: Hydraulic fittings transform the efficiency of a hydraulic system, making it far easier to ensure functionality, temperature, speed, and more.

- Improved durability: Hydraulic fittings play a key role in securing hydraulic systems against both general wear and contaminants. While it is still important to seek hydraulic hose repair near me every one to two years, this can help to keep high-end equipment like pistons and valves running more smoothly.

- Complete customisation: Hydraulics fittings make it possible to entirely customise a hydraulic system towards your applications and use cases, including across different sizing options, materials, and general configurations.

How to Maintain Your Hydraulic Fittings

Not only will poorly maintained hydraulic fittings fail to revolutionise your systems, but they’ll also leave your system at risk of things like leaks and outside contamination. As such, seeing true change from the hydraulic fittings you put in place is dependent on your ability to implement proper maintenance processes, which should include –

- At least a once-monthly maintenance routine

- Regular visual inspections

- Monitoring of hydraulic fluid temperatures

- Oversight of the correct hydraulic pressure ratings

- Immediate action in the case of leaks, including identifying the source of the leak and replacing any o-rings as necessary

- Regular cleaning of dirt, debris, and other contaminants

- Replacement and repair that’s always in keeping with manufacturer guidelines

Once you’ve taken care of these essentials, you’ll be able to see the full effects of what high-quality hydraulic fittings have to offer your system performance.