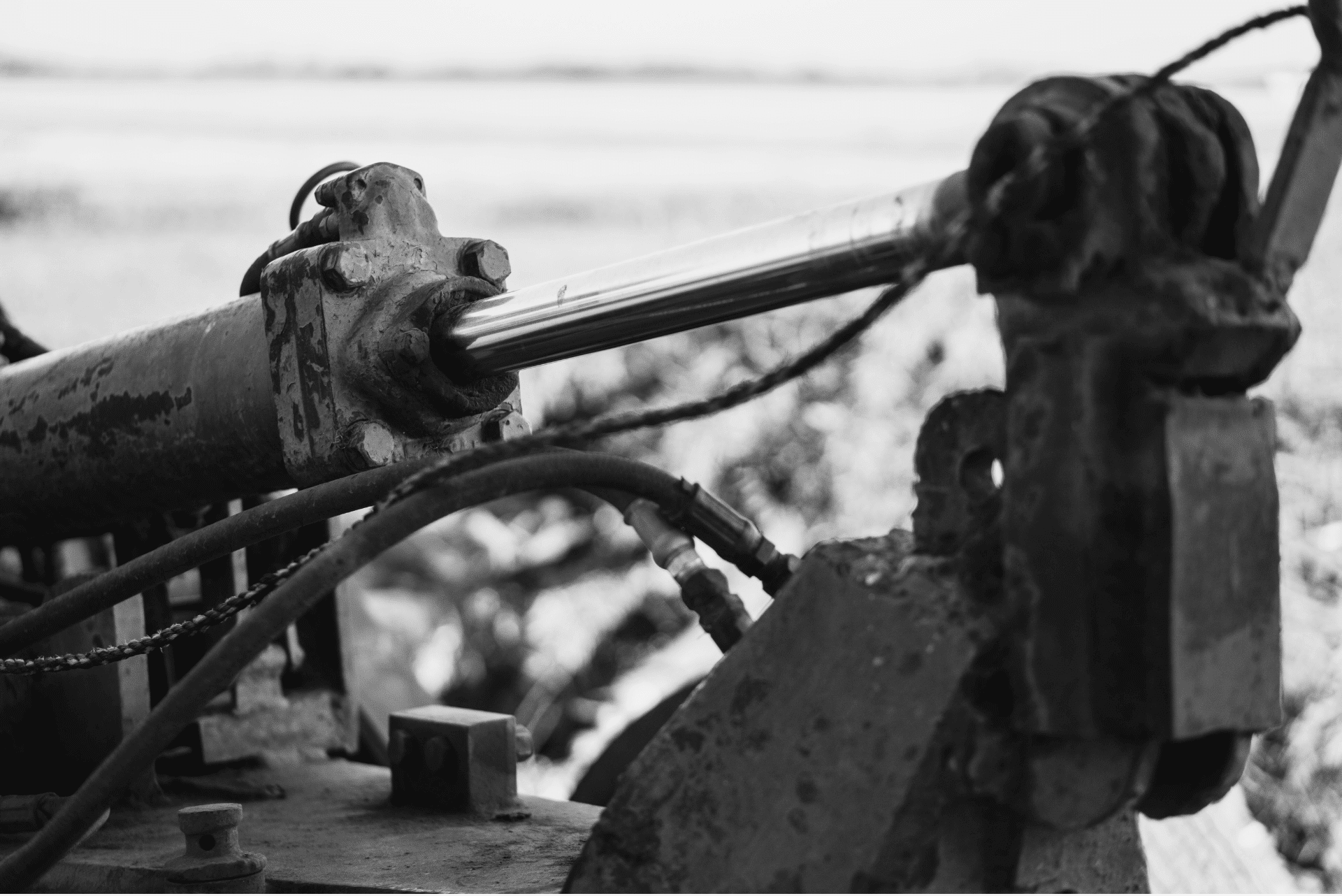

When working with heavy machinery in construction, mining, or other industrial sectors, a little wear and tear is to be expected from time to time. While some issues can probably be left until the next servicing appointment, a hydraulic ram leak must not be ignored.

A hydraulic ram leak is one of the most common signs of damage in custom hydraulic cylinders. When left untreated, the issue can cause safety risks as well as reduced performance. While our hydraulic repair Sydney experts can get your machinery back to full working order, knowing how to treat your hydraulic cylinder leak will enable you to maintain productivity and safety.

Firstly, remove the fluid

Before attempting to fix the hydraulic ram leak, our first tip is to test and drain the fluid. A hydrometer will quickly confirm whether the reservoir has a sufficient level of hydraulic fluid. If it does not, you can be sure that there is a fault, especially if you regularly top up the fluids.

To remove oil from the cylinder, you can remove the quick connect from its port and face it downwards with the fluid draining into a container. Aside from preventing mess, this step will subsequently allow you to test the cylinder and check whether your leak fixes have worked without ever confusing an old leak for a new one.

Replace the seals

Worn seals are the most frequent cause of hydraulic ram leak problems. Unless you are immediately aware of another fault, this is the first thing you should investigate. Even if you identify other issues, inspecting the seals is an essential part of a thorough hydraulic ram repair process.

If the seals are worn, replacing them will hopefully put an end to the leak. If it doesn’t, another problem still occurs. Once you have added new seals, you must also establish a new habit of lubricating them on a regular basis. This will slow the degradation process. It is particularly important if working with agricultural tools or other items that may be required on a daily basis.

Retighten all connections

In addition to worn seals, loose connections will lead to a hydraulic ram leak within your custom hydraulic cylinders. Therefore, you should take the time to visually inspect the connections for all engineering components. Any connectors that are loose or have been knocked out of position should be tightened. If the connector has become damaged in any way, you should replace this component.

As well as retightening the connections, you should check that all hoses are correctly attached. Again, if they have been damaged in any way, replacing the individual component will save you a lot of time, money, and hassle in the long run.

Polish rods

Cylinder rods are made from chrome, and can often become damaged by outside items as they leave the barrel. As well as causing cosmetic damage, this can impact performance levels and allow a hydraulic ram leak to emerge.

If you have the tools needed to polish the chrome, such as a clean and dry microfiber cloth, you could try to fix this issue on a DIY basis. In truth, it will only work on minor issues as deeper scratches will need to be professionally stripped and re-chromed (electroplated). Still, when scratched rods are the cause of leakages, it is a quick fix that you should be eager to try.

Add a stop-leak solution

Finally, you could add a dedicated Hydraulic Stop Leak solution to your custom cylinders. The material becomes a permanent seal on the hydraulic cylinder, which stops the leak. While it doesn’t technically stop the underlying cause, it is an ideal temporary fix that will stop the damage from escalating. It can also support the other steps like changing the connections and seals.

With the leak stopped and the machinery working as it should in the short-term situation, you can turn your attention to finding a permanent fix.

Call an expert today!

While the above tips and fixes will help treat the hydraulic ram leak, a professional hydraulic ram repair service remains the best solution by far. Here at FluidKraft, our hydraulic repair Sydney technicians can diagnose the source and severity of your hydraulic cylinder leak before implementing a fast and efficient restoration.

Whether it’s a simple fix or requires us to manufacture custom spare parts, like rods, doesn’t matter. We will ensure that the job causes minimal downtime for your business while ensuring that the repaired custom hydraulic cylinders are ready to provide years of reliable service. If nothing else, it is the only way to truly gain the peace of mind you deserve.

To learn more about getting your systems back under control, arrange a consultation today!