Hydraulic system repairs are essential for the efficient operation of hydraulic systems. Misaligned, worn, or damaged components can increase energy consumption and capital costs.

How Do You Diagnose Hydraulic System Issues?

You may have a problem with your hydraulic system if you notice:

- Noise emanating from the system

- Higher-than-normal temperatures

- Erratic operation

Clogged filters, damaged seals, and incorrect installation are the most common causes of these problems. However, the use of the wrong hydraulic fluid is also possible.

You may also notice hydraulic fluid escaping the system. Usually, it is clear. However, it may have water contamination if it appears milky.

What Tools And Equipment Do You Need For Hydraulic Repairs?

Hydraulic system repair may require any of the following tools and equipment to fix:

- Pullers

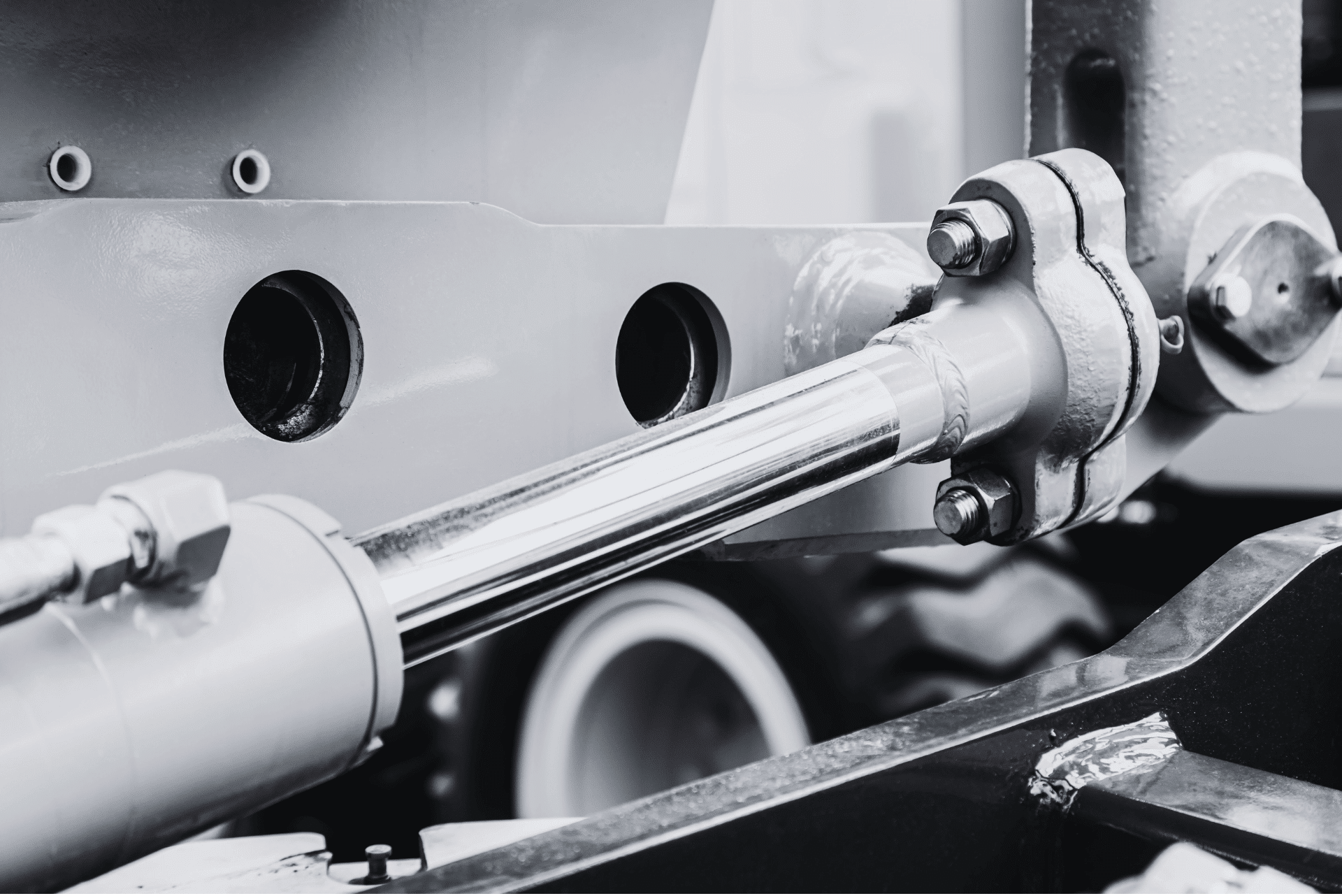

- Hydraulic rods and cylinders

- Pipe tools

- Pressure gauges

- Spanners

- Hydraulic hose cutters

- Pipe and tube cutters

- Flow metres

- Seal and O-ring pick sets

- Allen wrench set

- Sealant and thread tape

- Pipe threader and dies

- Socket and ratchet set

- Electrical multimeter

- Hydraulic cylinder repair kits

- Hydraulic fluid analysis kit

- The manual for your hydraulic system

- Adjustable pliers

- Tube benders

What Are The Best Practices For Efficient Hydraulic System Repairs?

When repairing a hydraulic cylinder leak or other issue, you should bear the following in mind:

1. The Impact Of Environmental Conditions

Environmental conditions can have a profound impact on how a repair performs. For example, changes in weather and temperature can affect the way seals expand and contract during operation.

Critically, operating conditions can differ from those present during repair work. Therefore, you will need to account for this as you fix issues.

2. The Tools You Will Use

Always prioritise the use of the proper tools during hydraulic system repair. Avoid using any non-standard tools or attempting to bodge a repair. Hydraulic systems require careful calibration. Slight changes in tolerances can have outsized effects on operating life and efficiency.

3. Taking Care When Working With Parts Under Load

Hydraulic systems require you to be careful when disassembling parts under load. Systems often contain pre-loaded springs that can release tremendous energy quickly, putting you at risk. Only uncoil them following manufacturer-defined processes.

4. The Underlying Cause Of The Damage

Carrying out repairs will only work if you address the underlying cause of the damage. Hydraulic systems can break down rapidly if repairs are incomplete or fail to resolve the primary issue.

Use instruments to check the hydraulic fabrication is within acceptable tolerances. Ensure materials and external casing are free from cracks and leaks. Check the hydraulic fluid for evidence of water. Inspect the interior of cylinders for evidence of abrasion and measure the trueness of the rod.

5. Any Signs Of Physical Damage

Professional hydraulic repair in Sydney visually inspects equipment. Use instruments to check hydraulic fabrication is within acceptable tolerances. Manufacturers can make errors.

Also, ensure materials and external casing are free from cracks and leaks. Check the hydraulic fluid for evidence of water. Inspect the interior of cylinders for evidence of abrasion and measure the trueness of the rod.

6. The Effects Of Friction

Finally, you should consider friction’s effects when carrying out hydraulic repairs. Use wear bands to guide rods through cylinders to reduce metal-on-metal contact as much as possible.

What Safety Precautions Should You Take During Hydraulic System Repairs?

You should follow standard safety precautions when repairing hydraulic systems. These will prevent injury.

First, read the manufacturer’s documentation on the hydraulic system you want to repair. This manual will contain critical safety information to keep you safe.

Next, ensure you wear proper personal protective equipment. Gloves and goggles protect you from hydraulic spray and moving parts. Hearing protection may also be necessary if you need to operate the system during repairs.

Always ensure you safety-isolate the hydraulic system before beginning work. De-energising it can help to prevent injury. Avoid a situation where you are working around pressurised units or coiled springs that could release.

When handling hydraulic fluid, avoid direct contact with the skin. The chemicals it contains can cause harm. Always use the proper handling equipment and containers, and follow standard disposal protocols.

Do not work in an enclosed, unventilated space. Ensure you have proper airflow unless using a back-mounted oxygen system.

Make sure you have proper training to fix the system. Don’t attempt an amateur repair.

And, finally, always use the right tools for the job. Don’t attempt a fix if you don’t have the necessary equipment. A poorly calibrated repair can put you and others in danger.

For the sake of productivity, profitability, and your sanity, contact our hydraulic repair experts today. We will find the most efficient and cost-effective solution in no time.