Hydraulic cylinder leaks are prone to various failures, including leaks. This post explores what causes these leaks, how to prevent them, and some detection techniques organisations use.

What Are Hydraulic Cylinder Leaks And Why Do They Matter?

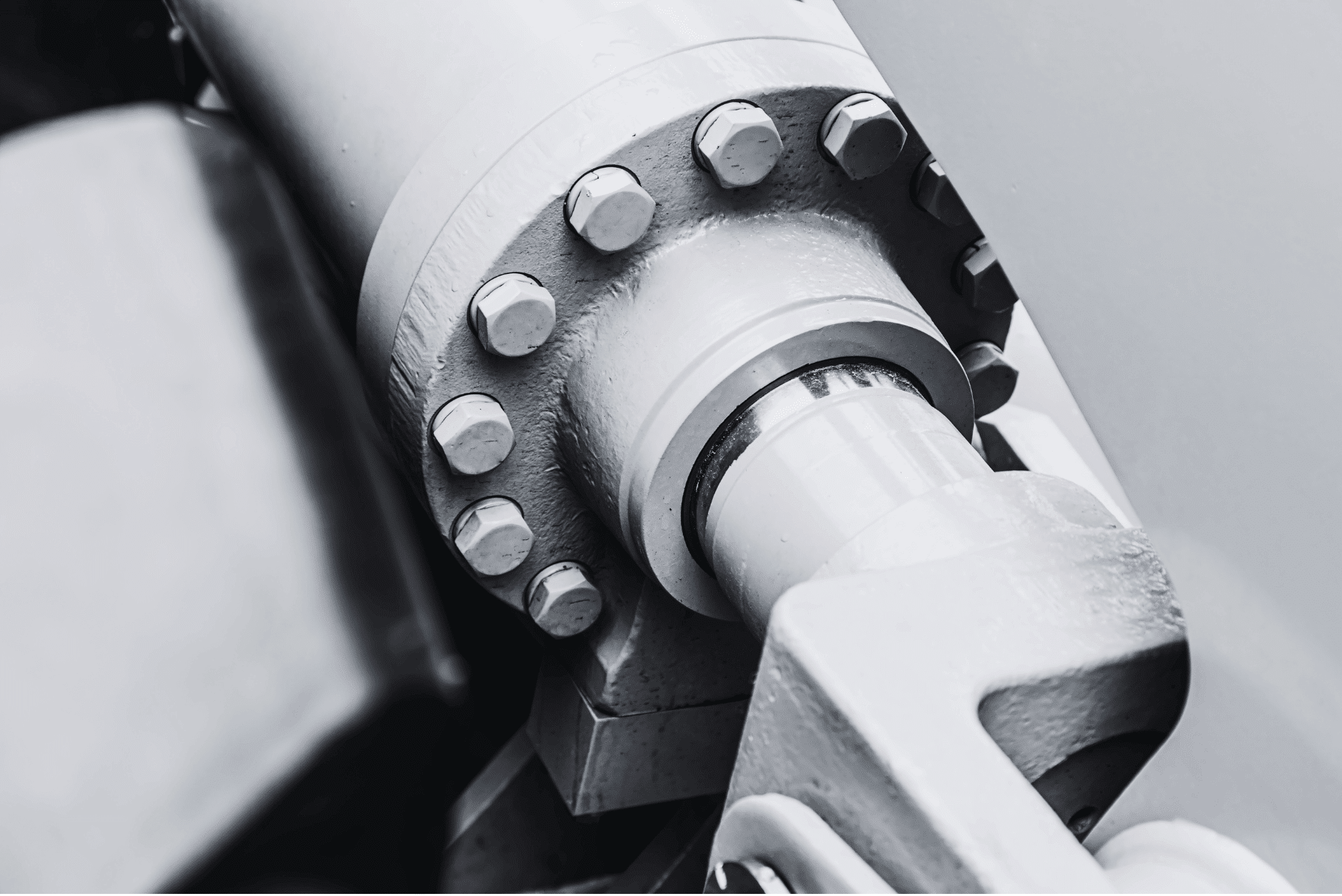

Hydraulic cylinder leaks occur when internal cylinder structures fail, allowing hydraulic fluid to move across the piston, leading to unequal pressure, spillage, and performance loss. Therefore, finding the source of leaks is essential. Organisations that respond rapidly can reduce downtime and repair costs.

What Causes Hydraulic Cylinder Leaks?

Several factors can cause a hydraulic cylinder leak.

Fractures

Fractures can occur because of excessive back pressure that damages seals on hydraulic systems. Professionals usually define this as pressures between 6,000 to 10,000 PSI, with the latter being the international standard for the maximum working pressure of high-pressure tools.

Wear

Wear is another cause of hydraulic cylinder leaks. This problem can occur because the equipment is old but, more commonly, because of poor maintenance and lubrication. It can also happen because of low-quality hydraulic fabrication.

Contamination

In some rare cases, hydraulic cylinders can become contaminated with small pieces of debris getting inside the chamber and causing damage.

Poor Installation

Poor installation is also a factor that causes cylinders to leak. Failing to follow the manufacturer’s instructions or using improper seals can lead to failure.

For instance, the rod in a hydraulic cylinder may not be parallel to the load direction. Asymmetric loads can cause bending, side loading and twisting, damaging the rod, seals, and other components and creating gaps that let fluid leak out.

Improper Piston Clearance

Improper piston clearance – the distance between the piston and cylinder bore – can also cause leaks. Most hydraulic cylinders permit a small quantity of hydraulic fluid to escape the main chamber to lubricate the piston to prevent metal-on-metal friction and provide clearance. However, a large or uneven gap can lead to excessive leakage.

Hardening

Finally, some hydraulic cylinder leaks result from hardening. This process occurs when systems generate excessive heat that accelerates material fatigue, increasing the risk of cracks and damage over time.

How Can Hydraulic Cylinder Leaks Be Prevented?

Fortunately, you can prevent costly hydraulic system repair by implementing basic maintenance approaches. Here’s what to do:

Maintain Hydraulic Seals

Seals are often the first components to fail on hydraulic systems. Therefore, maintaining them is essential.

To do this:

- Schedule regular seal inspections and checks

- Replace seals according to the manufacturer’s timetables, taking into account usage

- Look for evidence of hardening or cracking

- Take care of seals before installation to ensure they do not suffer damage

- Place seals carefully, avoiding forcing them or placing them in such a way that forces on them will be uneven.

Keep Rods Straight

You can also prevent hydraulic cylinder leaks by keeping rods straight. Misaligning can cause the rod to fail under load, causing parts to scrape inside the cylinder during operation. Over time, friction leads to corrosion, damage and mechanical inefficiency.

You can detect bent rods using a dial gauge. This tool will tell you if rod straightness falls outside of safe bounds.

Don’t allow machinery to operate with bent rods. Improper operation can lead to cylinder failure, forcing you to replace the entire system.

Reduce Fluid Contamination

Finally, you can reduce the risk of cylinder leaks by reducing fluid contamination. Particles in lubricating mediums can generate wear and tear on internal materials and force systems to operate outside manufacturer-approved parameters.

To prevent water from getting into your hydraulics, store fluids in airtight barrels away from moisture and temperature fluctuations. Only open new fluids in clean environments. Don’t expose them to dust or airborne contaminants.

How Can Hydraulic Cylinder Leaks Be Detected?

Detecting hydraulic cylinder leaks is challenging because you can’t always observe the leak directly. However, there are signs you can look out for to indicate a problem plus tools for more in-depth evaluations.

Here are some of the signs your system is leaking and you require hydraulic repair in Sydney:

- Increased operating temperatures

- Reduced performance on standard tasks

- Frequent breakdowns

- Rod creep, where the rod moves out of the desired alignment

- Decreased control over hydraulic processes and functions

Unfortunately, some of these symptoms are non-specific; they may indicate other issues. For example, weak springs on relief valves can have the same effect on fluid energy loss.

Therefore, many organisations install flow meters on their drains and pumps. Engineers replace components when measured variables fall outside of standard ranges.

It is also possible to detect leaks using ultrasonic tools. These fire sound waves at cylinders and feed information back to a computer, showing the size and location of the leak.

Fluid Kraft is a reliable and experienced hydraulic cylinder repair and overhaul service provider in Australia that can help you with all your hydraulic system repair needs.

Contact us today to arrange a full consultation.