Hydraulic systems are found in many places across industrial settings. Cylinders, hoses, and pumps are just some of the hydraulic components that may be present in hydraulic equipment. Naturally, these systems require proper maintenance and may need to be repaired when they start to deteriorate or are damaged. Getting hydraulic repair right is crucial to help protect and preserve valuable machinery using hydraulic systems in these environments.

At FluidKraft, we offer hydraulic repair in Sydney to meet all of your business’s needs. Our expert maintenance and repair technicians are capable of caring for both small and large hydraulic systems. As experts in hydraulic repair, we’re also here to provide you with the best advice on how to carry out repairs efficiently and effectively.

The Importance of Maintaining Hydraulic Equipment

When a problem occurs within a hydraulic system, it can usually be repaired. However, it’s also essential to consider the importance of maintenance and its role in preventing the need for repairs. A well-maintained hydraulic system can protect the equipment, helping with the avoidance of repairs that could be more costly and time-consuming to deal with compared to regular maintenance. Scheduled maintenance keeps the system safe and functioning, preventing the loss of productivity and production.

When Should You Replace a Hydraulic Part?

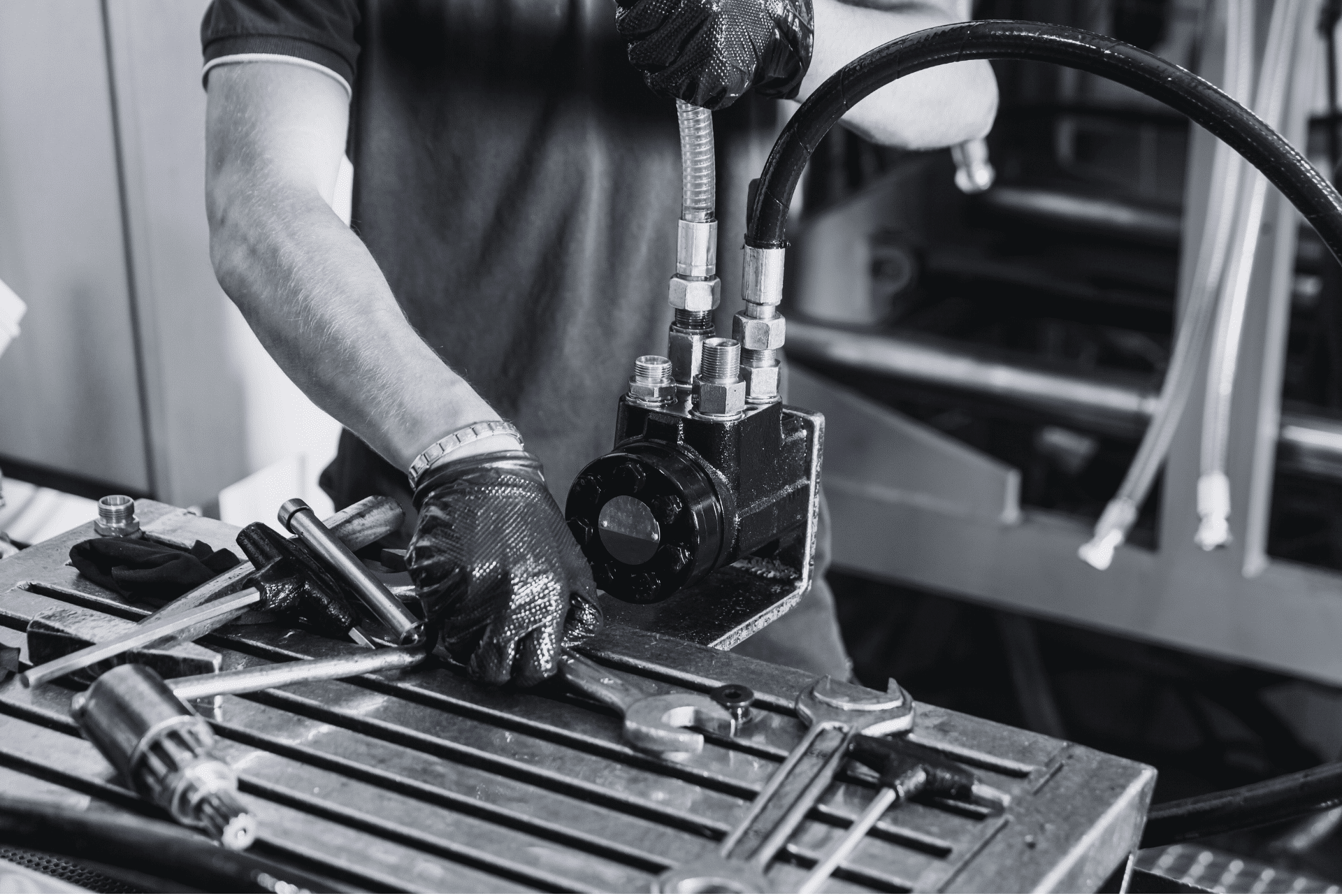

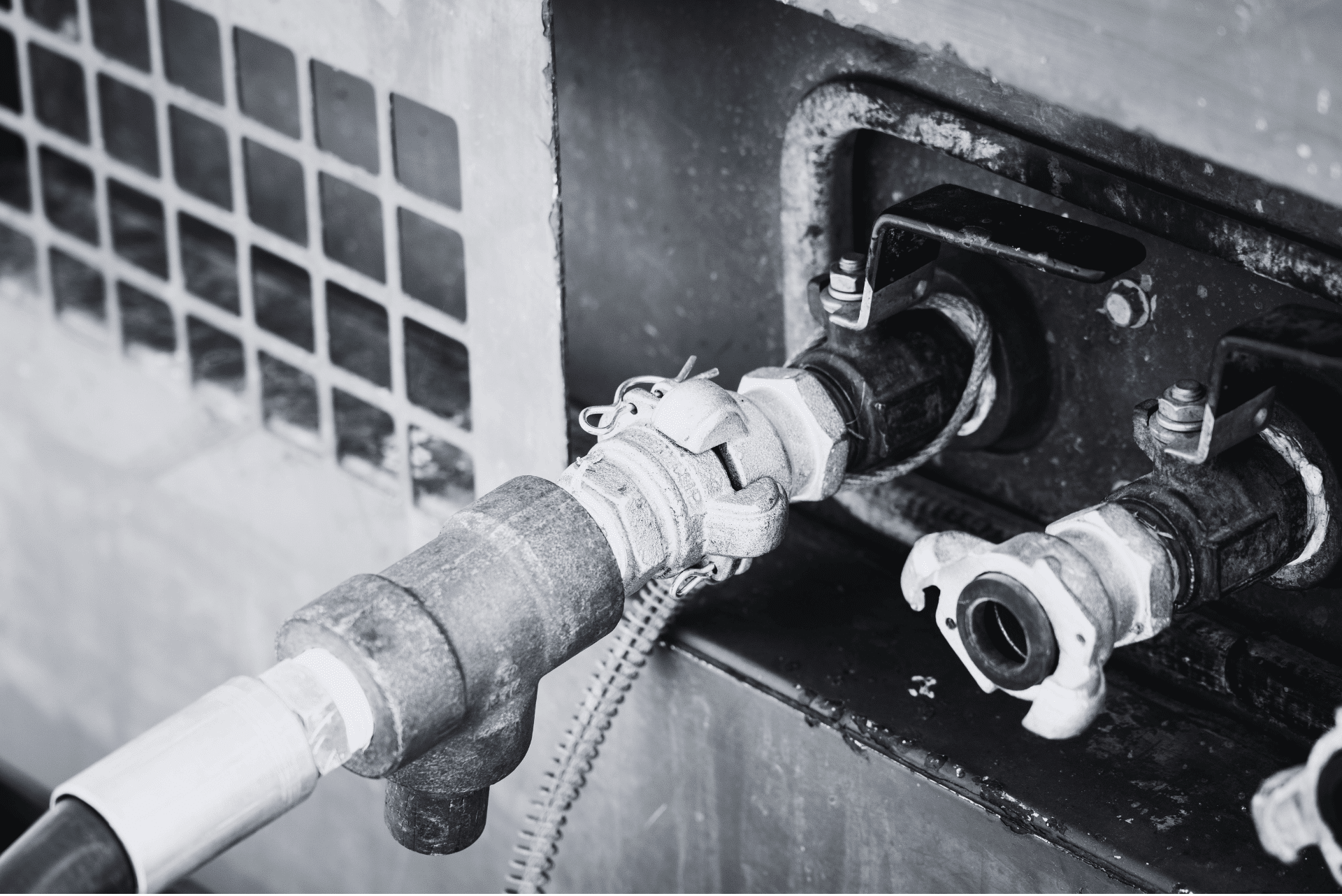

Many parts within a hydraulic system experience wear and tear over time. Eventually, they need to be replaced to keep the system functioning as it should. These include parts such as seals, hoses, and fittings, which can start to break down and cause leaks or other problems. It’s often best practice to periodically replace these parts before they start to degrade too much, rather than waiting for them to fail and potentially cause more significant problems.

How Can You Identify the Cause of a Leak in a Hydraulic System?

Leaks are a risk to be aware of when dealing with any hydraulic system. When a leak is present, it can lead to further problems and the equipment may eventually be unusable. However, you can sometimes be aware of a leak without knowing the true cause. Identifying the source of the leak is the first step to making the right repairs.

There are various methods used to find leaks in hydraulic systems. If you’re dealing with a small hydraulic system, you may be able to find the issue yourself. Depressurising the system allows you to check all of the joints, seals, and connectors to identify any broken parts or signs of deterioration. However, you may need professional assistance for larger systems. An expert mechanic will use specialised equipment to find the source of the leak. Dye is sometimes used to find the location of a leak. By introducing dye into the fluid, you can then observe where the colour is noticeable on the exterior of the system.

Standard Troubleshooting and Maintenance for Hydraulic Systems

Some standard steps can be taken to maintain the health of a hydraulic system and identify the cause of any problems that occur. Keep your hydraulic equipment in good condition with the following tasks.

- Change filters, following manufacturer guidelines

- Inspect seals, hoses, and fittings, and replace them when necessary

- Monitor temperatures within the system and heat or cool as needed

- Find and address leaks

- Listen out for unusual noises and identify their cause

- Monitor vibrations to look out for issues with pumps, motors, or other components

- Test pressure and flow rates and make adjustments to ensure they align with the system specifications

What Steps Should You Take When Repair Is Required?

Follow these important steps when carrying out repairs on key hydraulic parts such as cylinders.

- Assess the equipment or part to find the cause of the problem.

- Carry out safe disassembly of the part, keeping track of components and where they go.

- Clean and inspect each component to identify potential issues and parts that need to be replaced.

- Replace components that show signs of wear and tear or have been damaged

- Replace fluid and flush the system.

- Reinstall and calibrate parts to ensure their proper functioning.

Remember that preventive maintenance is just as important for hydraulic systems as making timely repairs. Regular maintenance will help to prevent major issues, which might be more costly and time-consuming to repair. The FluidKraft team can help with both maintenance and repairs.

Expert Hydraulic Repairs and Maintenance from FluidKraft

Call on FluidKraft when you need help with the repair and maintenance of your hydraulic systems. Our expert team can work on systems of all kinds. Contact us today to organise our hydraulic repair service.